SLICE HOUSE - DWELL

Since first learning about the Dwell Home project from Dwell Magazine Editor-in-Chief Allison Arieff, we have been intrigued and excited by this fresh approach to making good quality design and construction more affordable. While these goals are easily embraced, and frequently discussed, the limited availability of houses that make successful use of prefabrication demonstrates the difficulty in moving from concept to reality. We understand the Dwell Home project as a vehicle for narrowing this gap, by challenging architects to demonstrate their concepts as applied to a specific site, specific clients and program, and a specific budget and time frame.

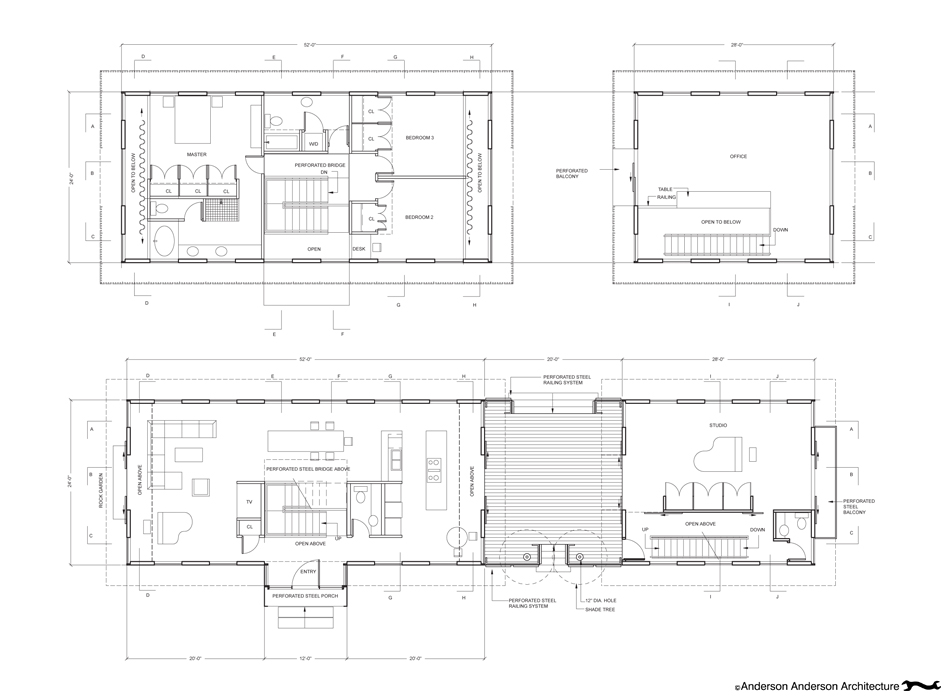

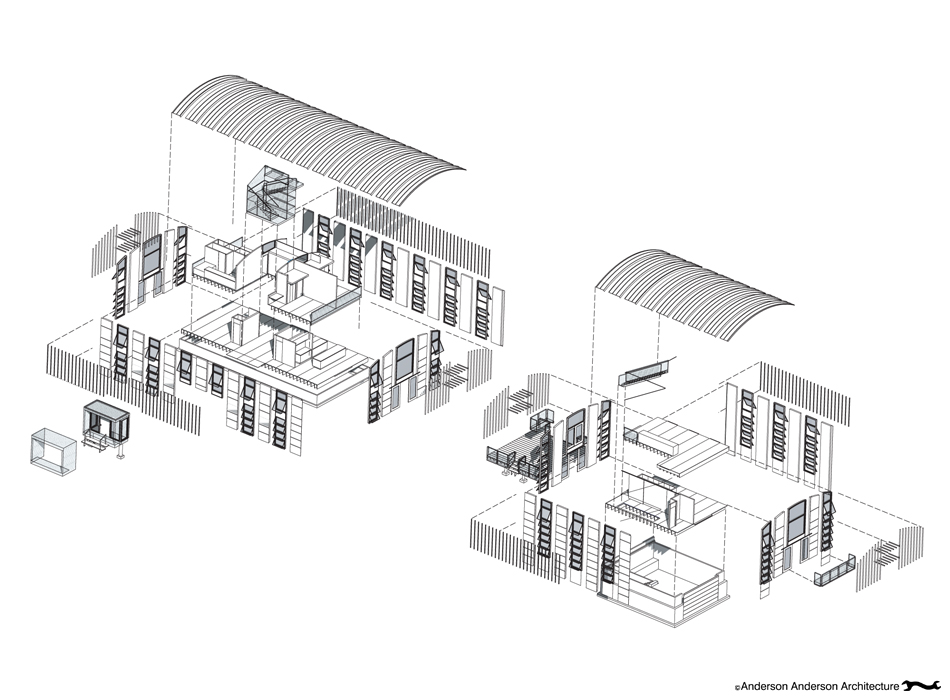

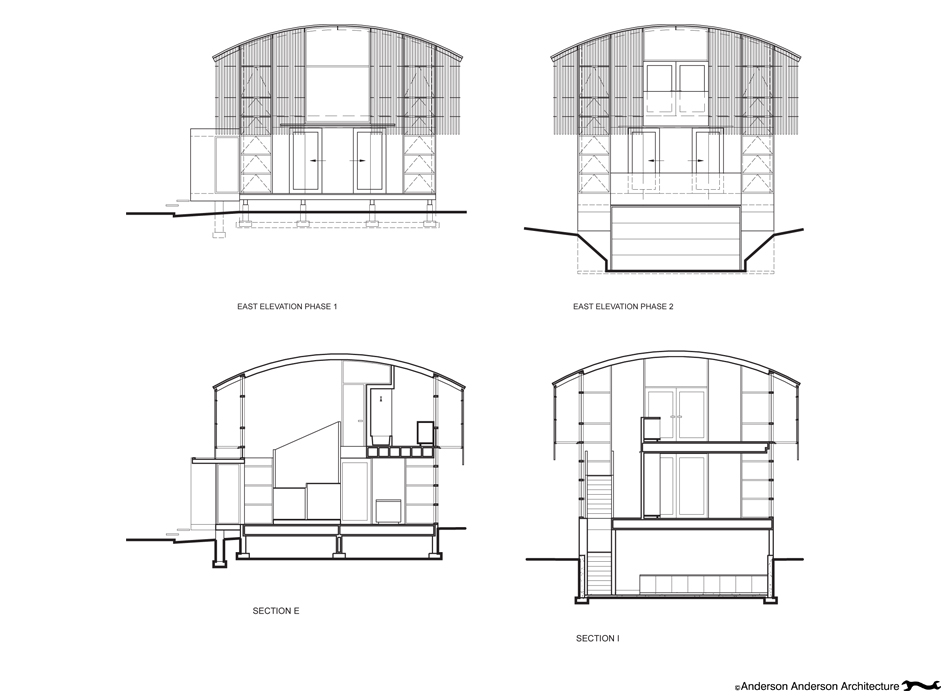

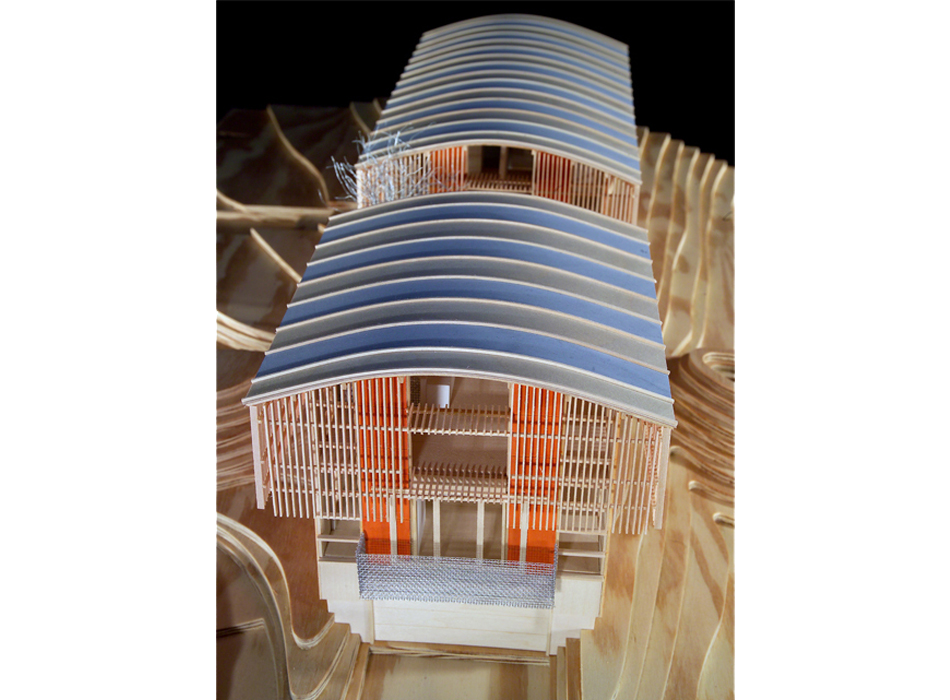

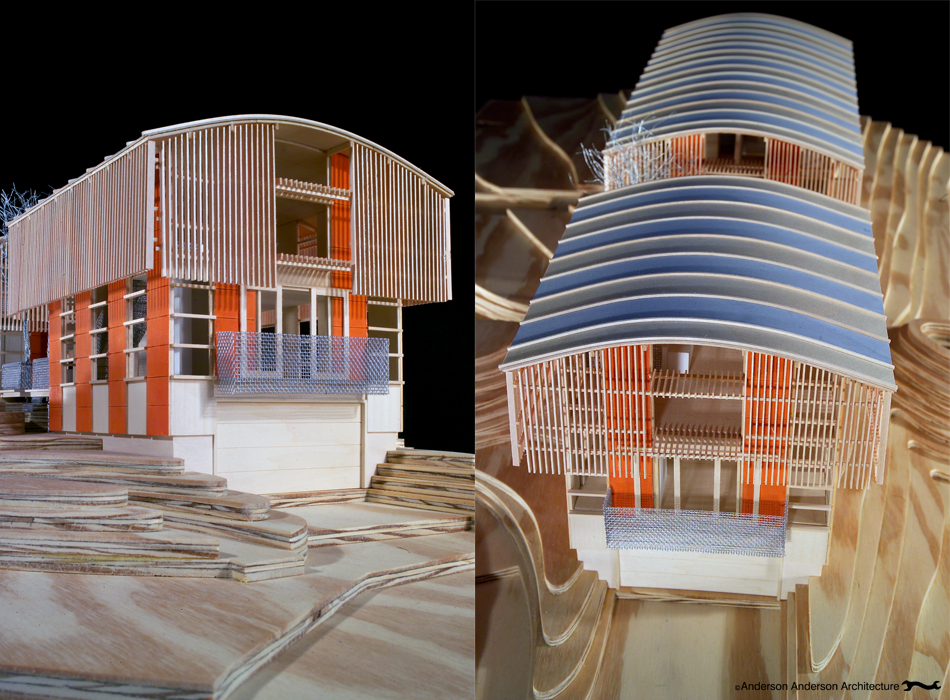

The Anderson Anderson/Dwell House for the Tung-Wieler family is designed as a cost, time and resource efficient means to construct a spatially rich living experience on a particular site. We have worked to balance an interest in developing a kit of rational building elements with a focus on demonstrating their case study implementation, while at the same time satisfying the needs and aspirations of the Tung-Wielers and demonstrating simple means of carefully deploying a relatively universal prefabricated building system into a unique landscape and climate.

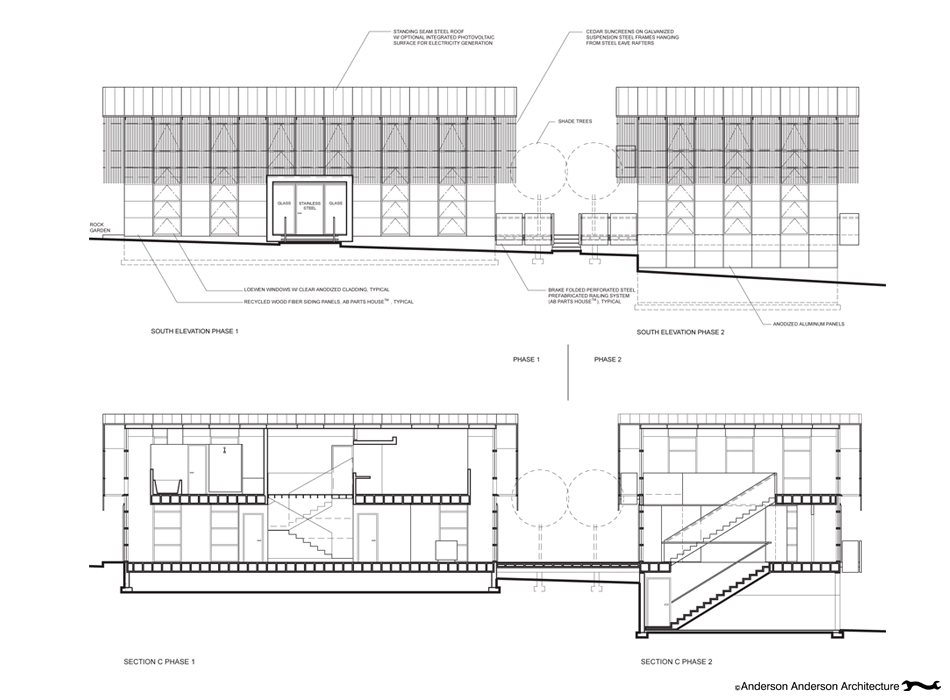

We have approached this project as the development of a prototype for a pre-fabrication and project delivery system that focuses on the adaptation and implementation of readily available materials and building techniques, rather than as a platform for experimental technologies. Our experience in both custom and prefabricated affordable construction suggests that the time, cost, and prototyping ambitions of the Dwell House project can only be achieved with a highly realistic approach to selecting and adapting already existing components, while organizing these elements into a system that will point the way toward significantly greater cost and time efficiencies once applied to higher volume production.

One of the lessons that can be learned from the many previous failures in prefabricated housing production is that uniquely proprietary systems of single-source components are too costly to develop. We believe that the most effective path to achieving the benefits of prefabrication comes from an incremental transition from site-based craft and assembly, to off-site componentization. This is not a radical approach—this process has been underway for a century or more, with the standardization of the 2×4 stud marking one of the most obvious examples of successful prefabrication. Building components are increasingly available as manufactured assemblies ready to be deployed. The greatest weakness in the widespread implementation of prefabrication into the homebuilding industry has been the lack of designers interested in integrating existing products and systems into appealing and affordable buildings. The development of a viable pre-fabricated housing market responsive to a demand for high-quality design and construction will open a vast world of new opportunities for future exploration of experimental approaches to material use and production techniques

In this project, we have used only readily available, off-the-shelf materials and pre-fabrication systems that we know can be financed through standard banking channels in a timely manner, and permitted by the applicable building department without extensive review of unfamiliar construction methods. The house emphasizes the products of the manufacturers who have sponsored the competition, and further develops detailed opportunities to greatly expand the sponsorship of the actual construction project by showcasing many products of large manufacturers who will need to be influenced to help develop a strong pre-fabricated modern housing industry in the near future. This house represents a design solution that grows out of our many years of experience with bankers, building officials, construction workers, and product manufacturers, and reaches toward affordable new qualities of life.