HOT WHITE ORANGE

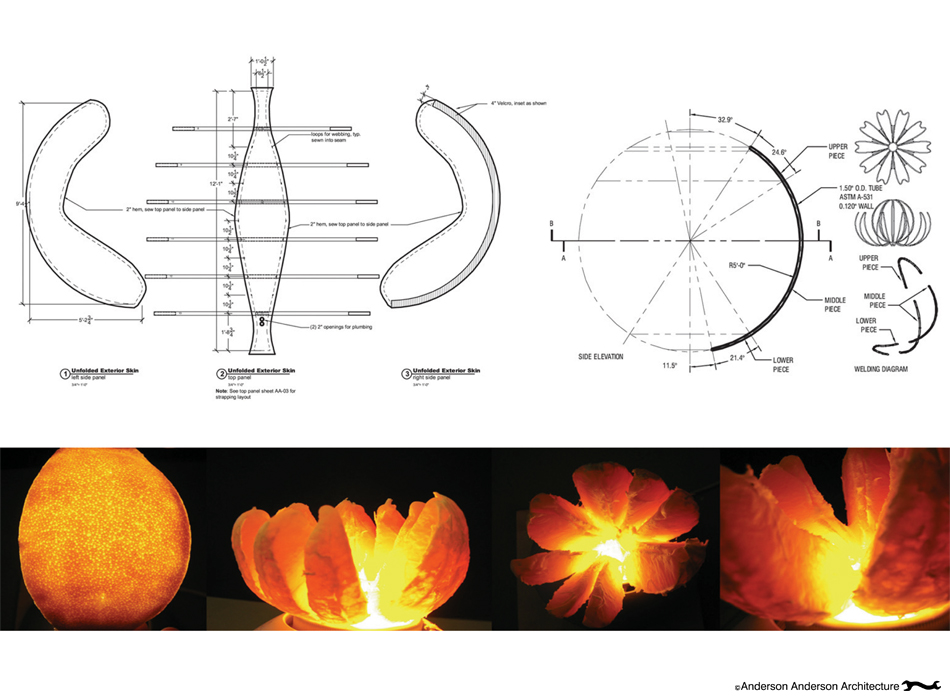

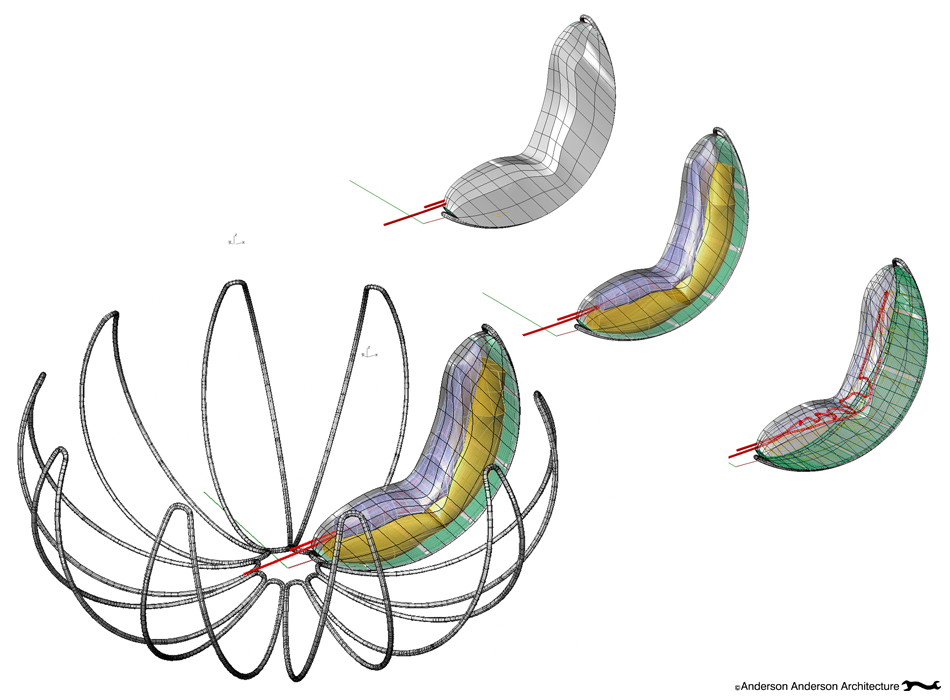

Hot White Orange is a solar heated, portable amphitheater sized to comfortably accommodate thirty people in conditioned comfort during outdoor events and performances. The project was commissioned by UC Berkeley using privately donated funds and services, and was a collaboration of professional architects, Bay Area industrial fabricators, and 22 architecture students. The design team was divided into a number of separate sub-teams responsible for design and production of specific components of the project. To maintain integration and coordination, the form and general approach was established in one group meeting at the beginning of the project. To minimize gross-scale design negotiation, the formal structure was established as precisely that of the orange fruit. With this parameter, a simple 3-dimensional digital model was created as the common base geometry for the project, within which all further design and fabrication issues would be negotiated. The size of the object was established as a 10’ diameter sphere. The portable outdoor amphitheater program generated functional criteria for weatherability, mobility, and outdoor seating comfort. The project has a steel frame exoskeleton, air-filled bladder internal structure, hydronic heating coils circulating hot water supplied by pump from a satellite solar heating bladder. The heating coils are wrapped around water-filled thermal ballast blankets beneath the external vinyl skin, which is lit from within. The orange fruit serves as both formal geometry paradigm as well as inspiration for the complex interior structure and mechanical systems of a living, pulsing, vascular bladder architecture. The project generated tremendous new insights into rich alternative worlds of cad-cam fabrication technology available in structural and material industrial processes not usually engaged in typical building construction.

Notable Points:

An experiment in pro bono service to a public institution, integrating the services of architects and Bay Area manufacturers and fabricators who both donated services and included student volunteers as an educational process allowing real-world, full-scale design and building experience in a manufacturing environment.

An experiment in cad/cam fabrication technologies not typical in everyday building construction, with the parallel intention of making solar technology interesting to designers

Statement of Criteria and Design Solution:

Budget $15,000 in private donations, plus donated services

Project Information:

Wurster Hall

University of California, Berkeley

Berkeley, California

Size: 24’ diameter, 10’ height(closed), 452 square feet

Cost: $13,000 total

Project Team:

Mark Anderson, AIA

Peter Anderson, AIA

Yuki Bowman

Grant Chang

Neil Dau

Bill Glauch

Emily Behoar Gosack

Christine Chang

Lamia Bensouda

Myrto Milliou

Chris May

Margaret Sledge

Joe Jacoby

Amy Van Nostrand

Kevin Markarian

Claudio Martonffy

Danny Lee

Cari Rosner

Nash Hurley

Ed Rendle

Natalie Kittner

Tzu-Tsen Kuo

Reiko Matsuo

Goran Wang

Toben Wyndahl

Byron Chang

New World Manufacturing

Architect: Mark Anderson, FAIA Peter Anderson, FAIA

Owners: University Of California, Berkeley

Engineering consultant: Terry Nettles, P.E.

General Contractor: University of California, Berkeley

Photographer: Anthony Vizzari