Cantilever House

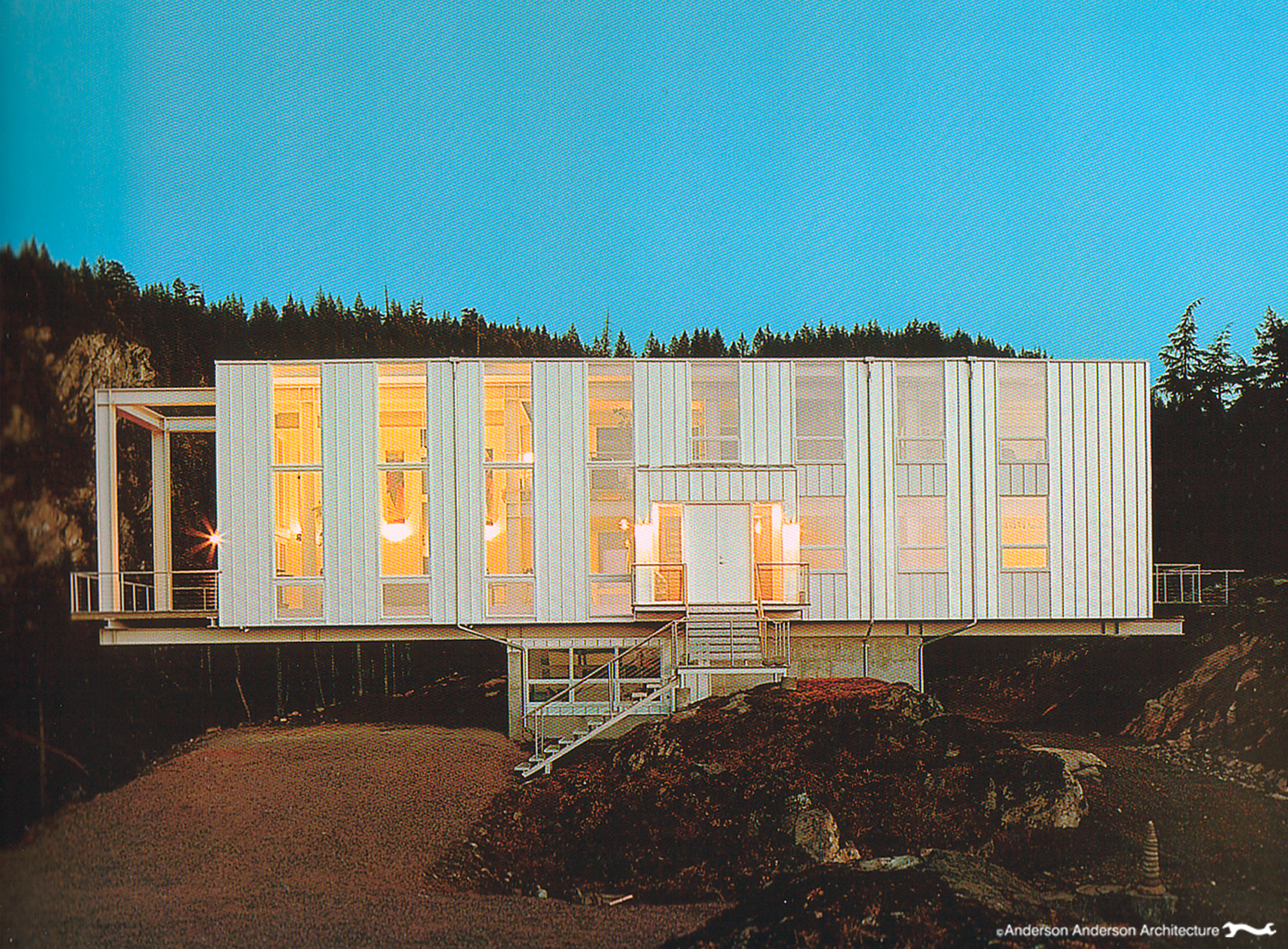

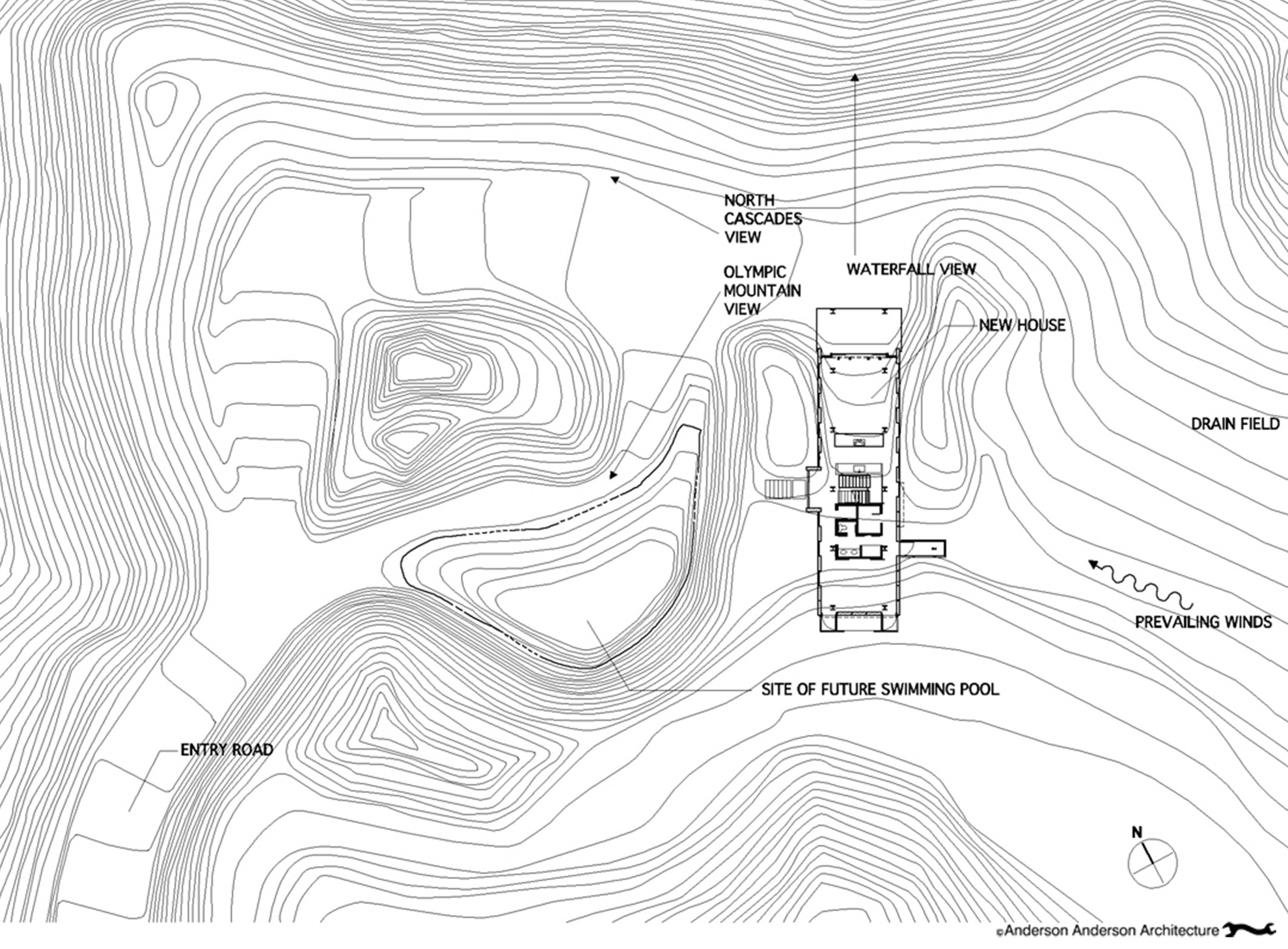

This prototype is to be built near Granite Falls, Washington, in the Cascade Mountains about 50 miles north east of Seattle. A second prototype is in the planning stages for an urban site in San Diego. This house is part of a series of projects that explore the opportunities for using prefabrication techniques and new building construction methods and materials to build low cost, high quality, site-adaptable and program-adaptable manufactured buildings.

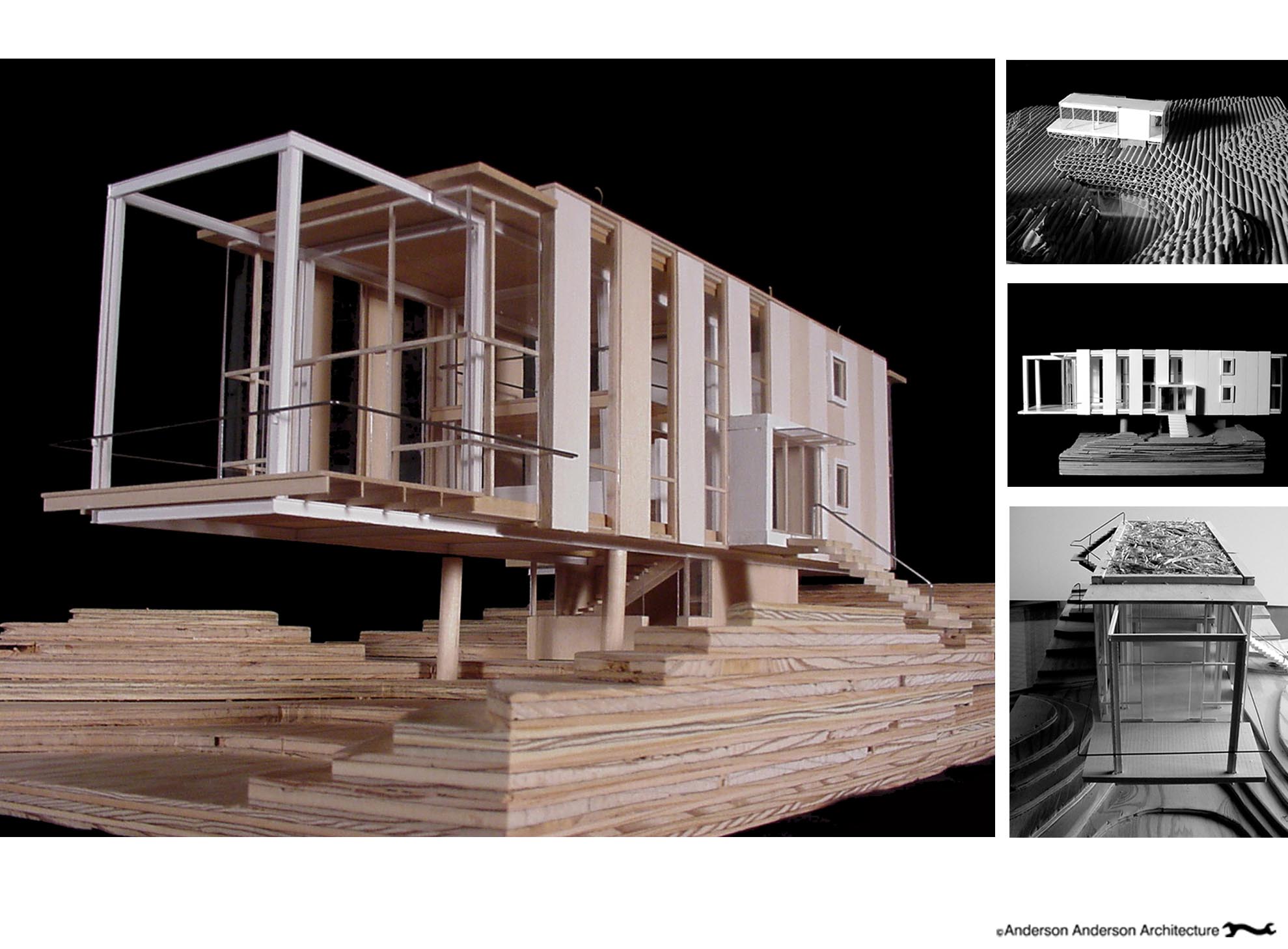

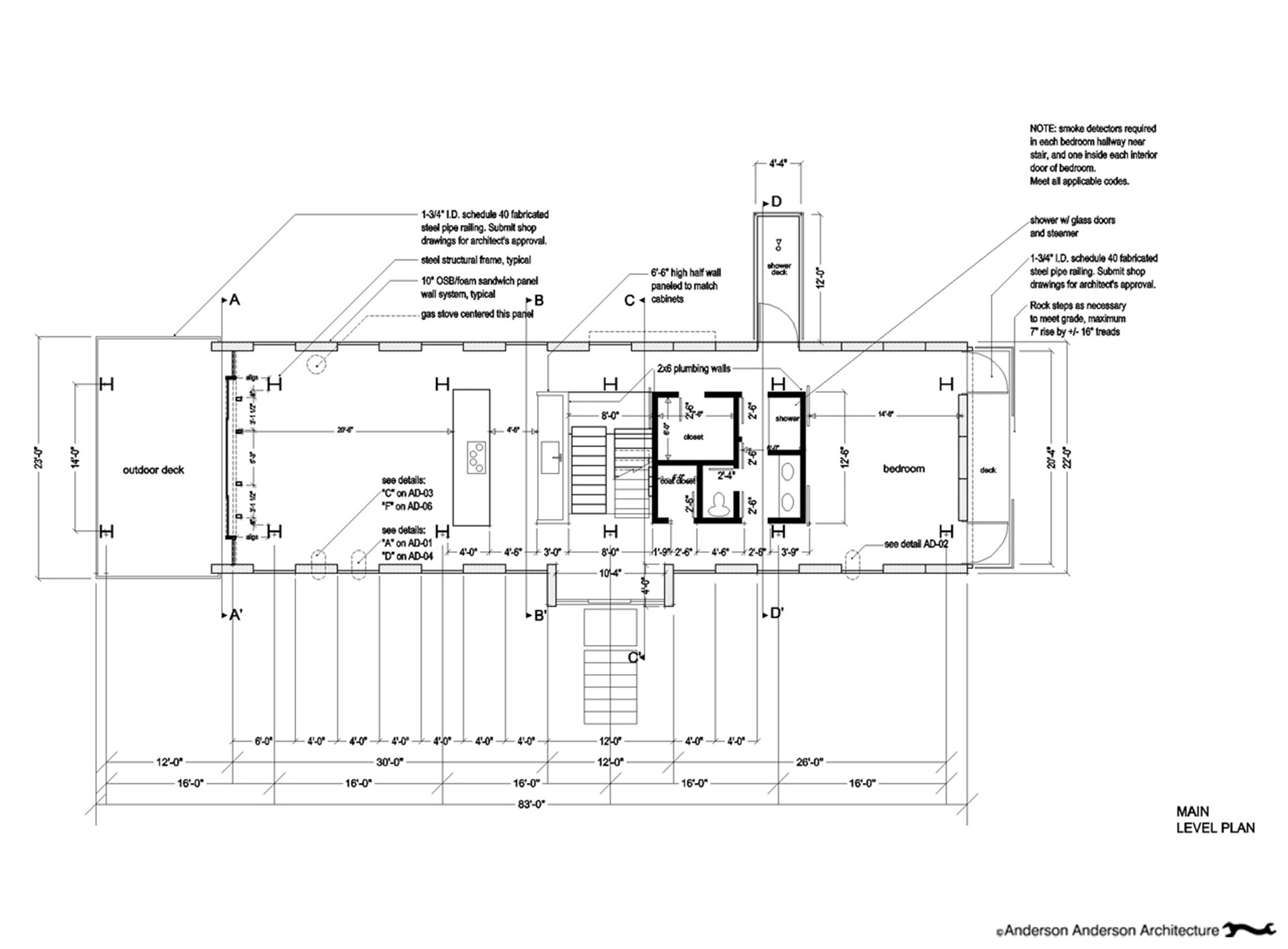

Although the building site for this prototype has quite unrestrictive zoning constraints, the challenging topography and geotechnical conditions play a strong role in defining the overall design strategy for this project and as a prototype for difficult hillside sites. The small ground floor building footprint/foundation reduces the cost of this expensive area of the house, and allows the points of attachment to adapt to varying slope and soil conditions with minimal disruption of the natural topography.

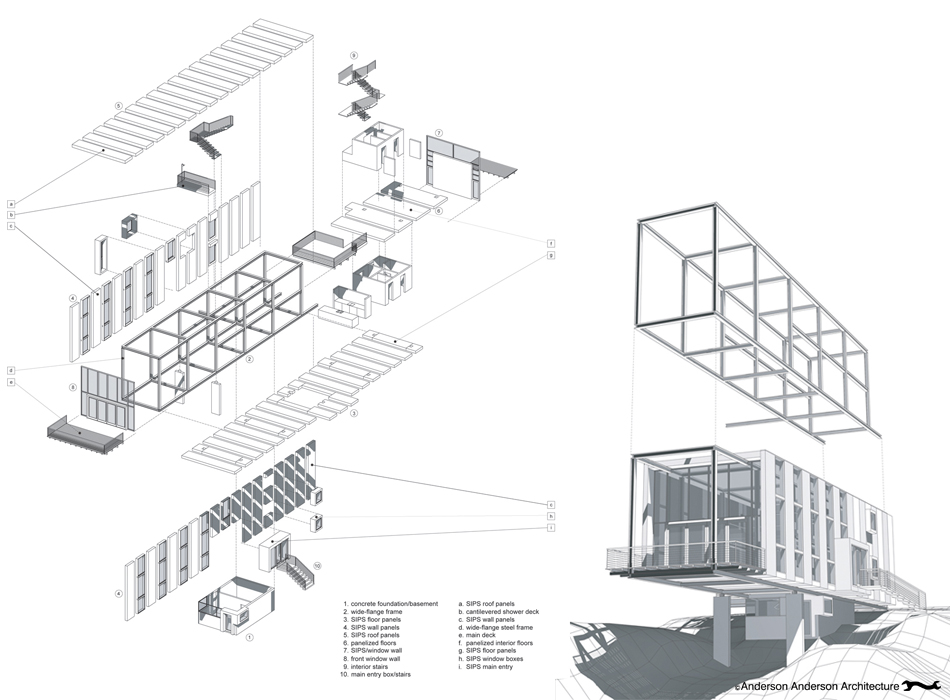

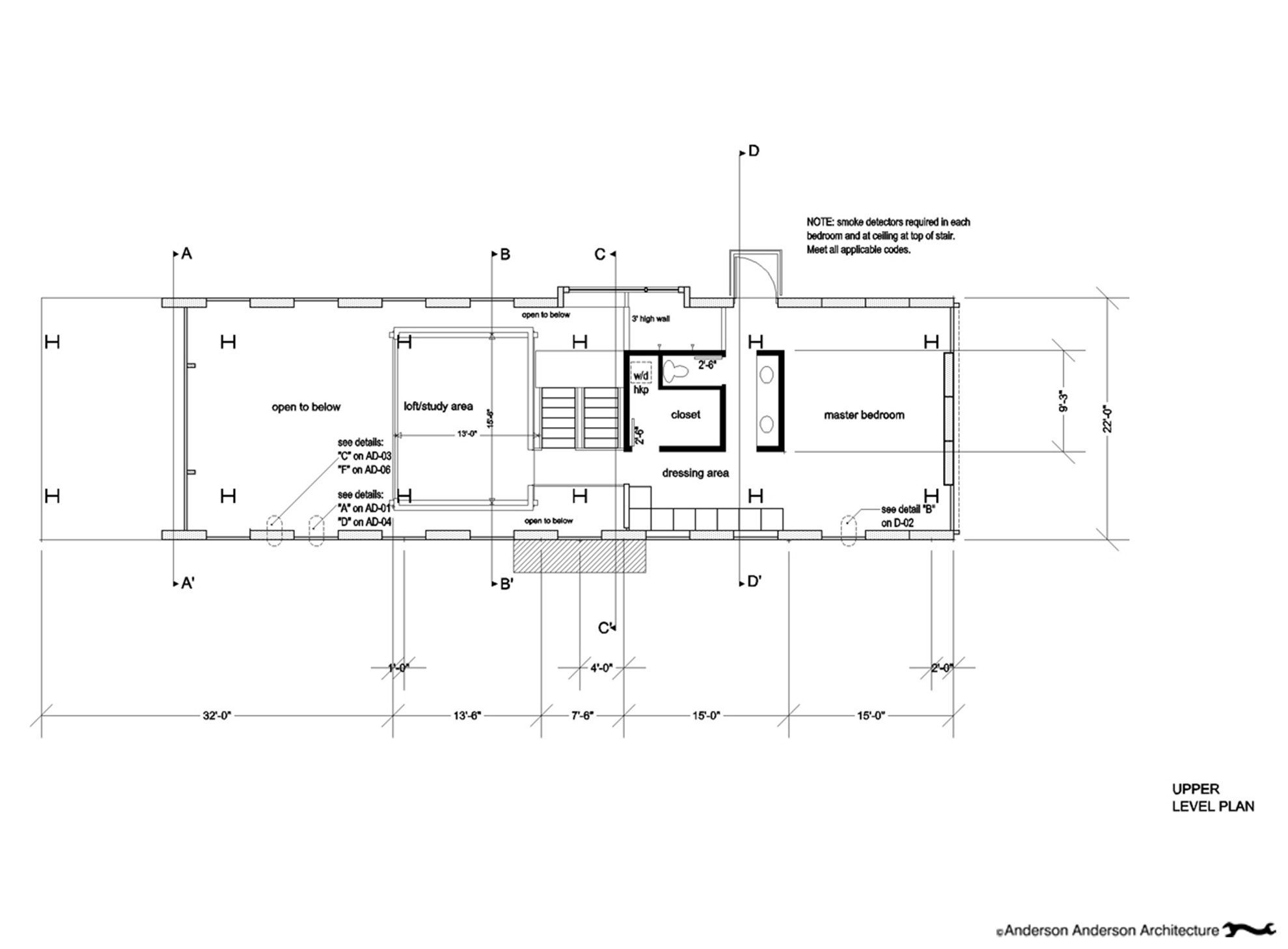

The building system is a marriage of two common, standardized, mass-produced building elements – a prefabricated steel structural frame (of the type commonly manufactured for light-weight commercial structures), and a structural insulated panel system (SIPS) that provides all non-glazed building envelope areas. Significant economies are achieved by using the same low-labor structural panels for walls, floors and roof. The system is designed around a small number of interchangeable, rearrangeable assemblies for efficiencies of time and cost, and to minimize the environmental impacts of on-site construction.

Although the materials and methods of construction are chosen for efficiency and affordability, the underlying design principles guiding the development of the system have the larger goals of producing affordable, high quality buildings that offer variety, adaptability, convertibility, strength, simplicity, spatial richness, and optimized access to views and light.