Arboretum of the Cascades

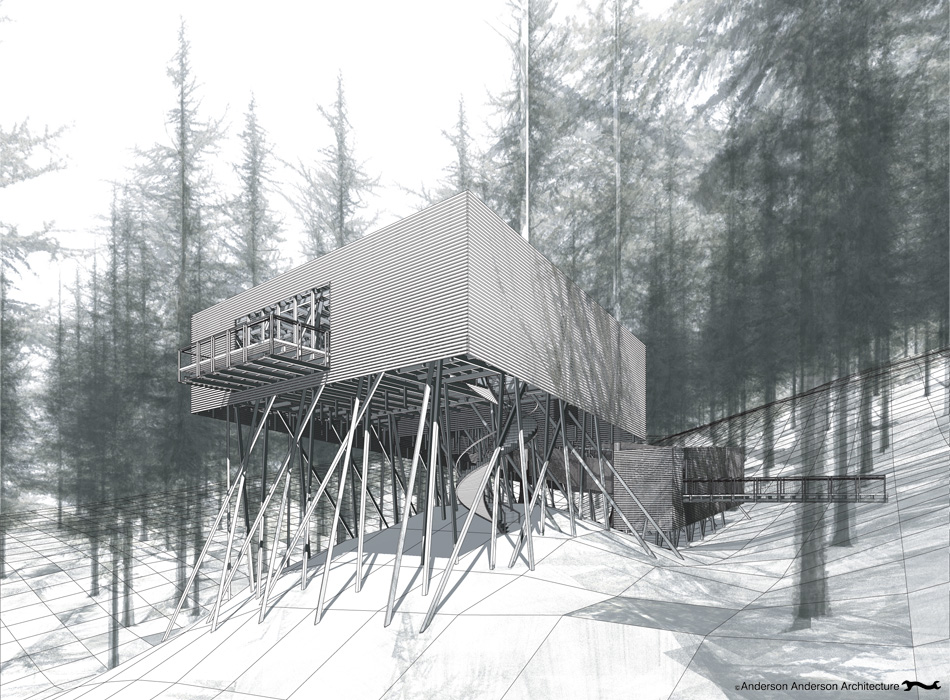

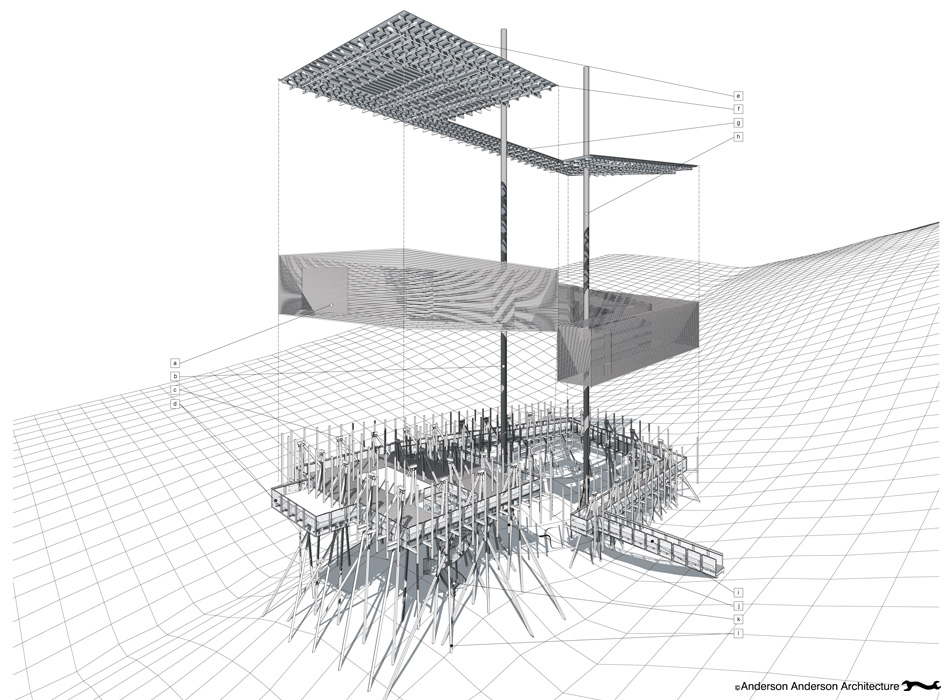

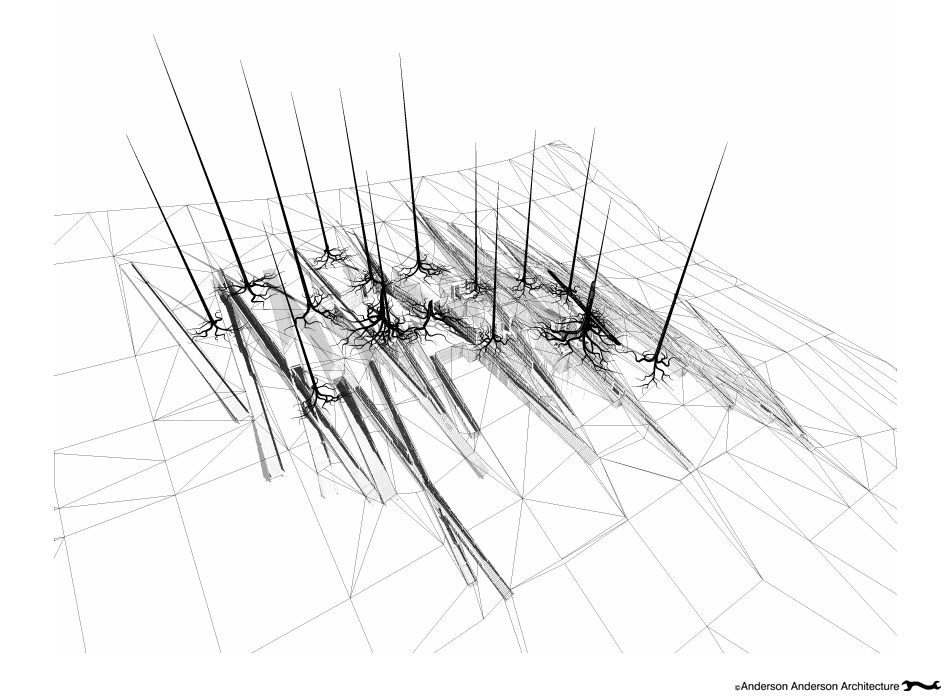

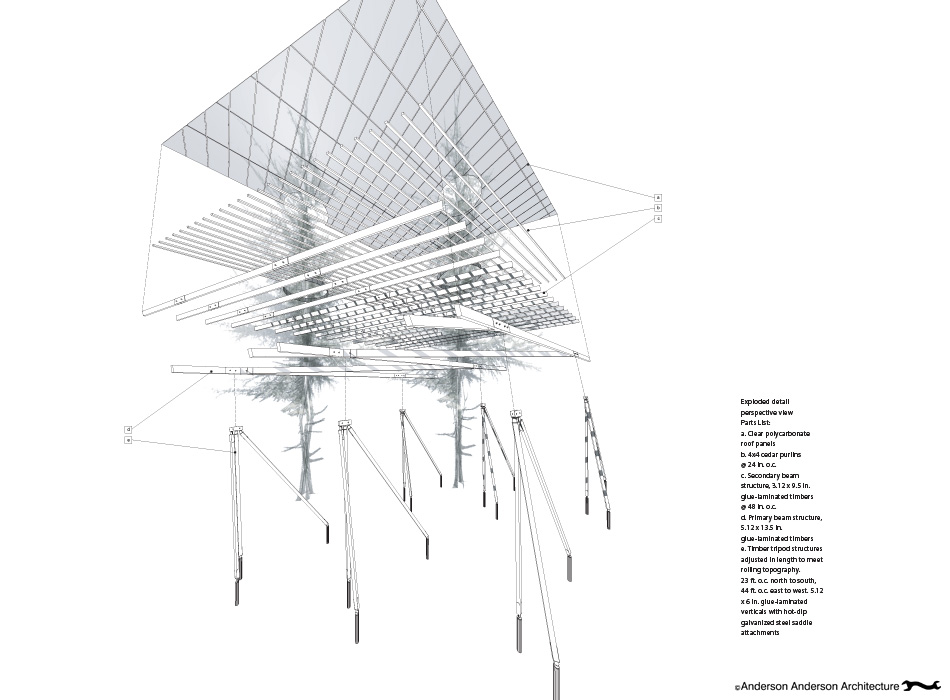

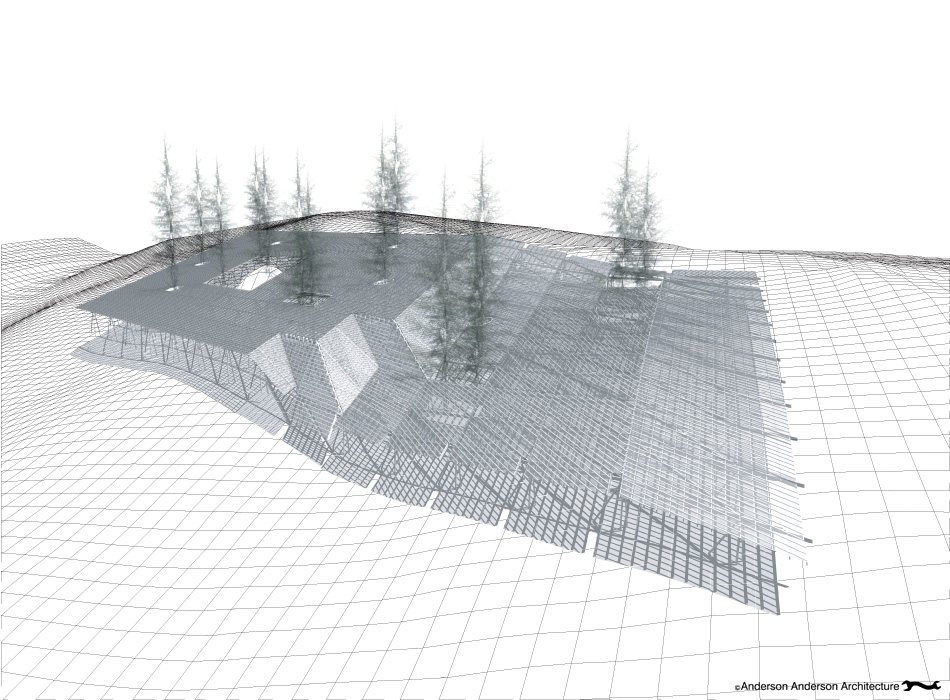

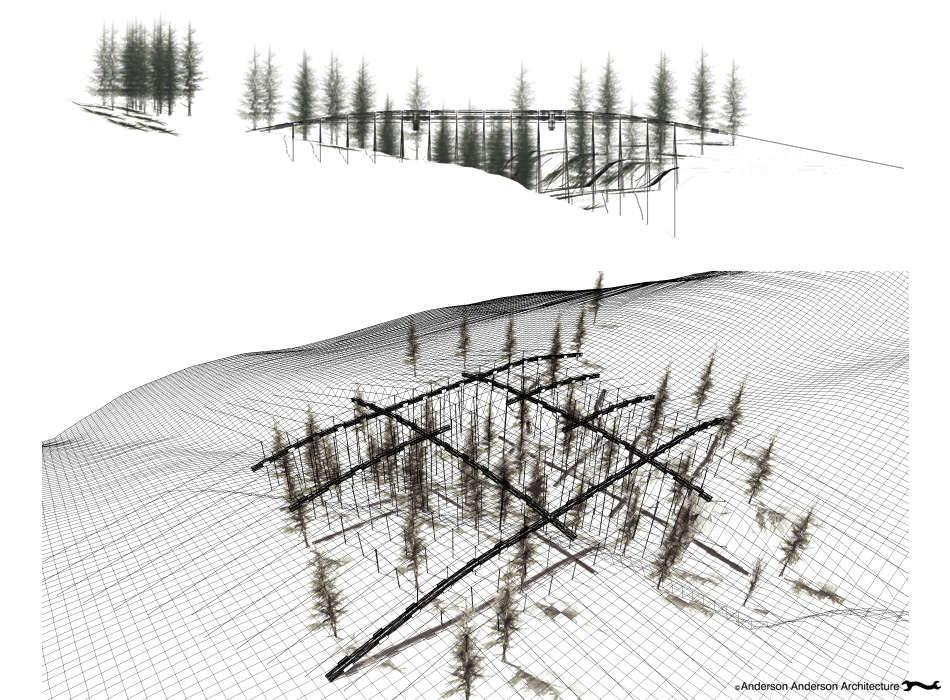

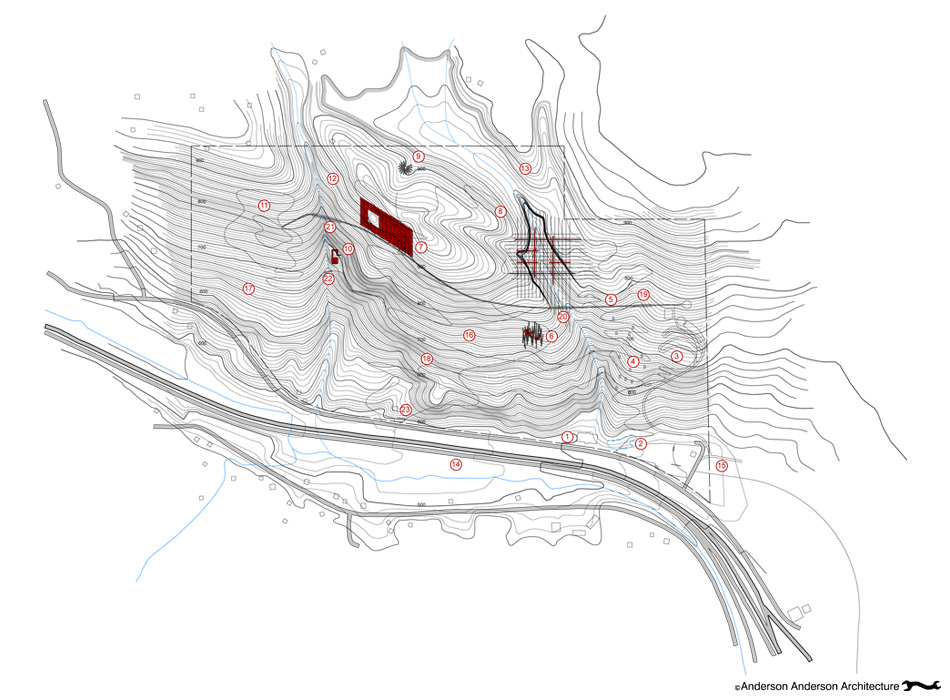

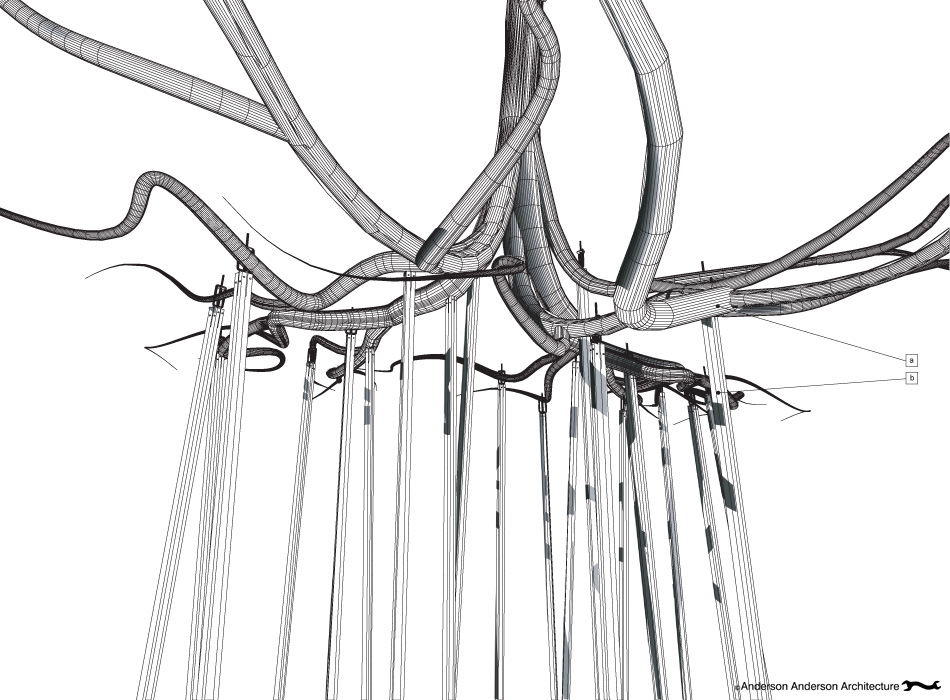

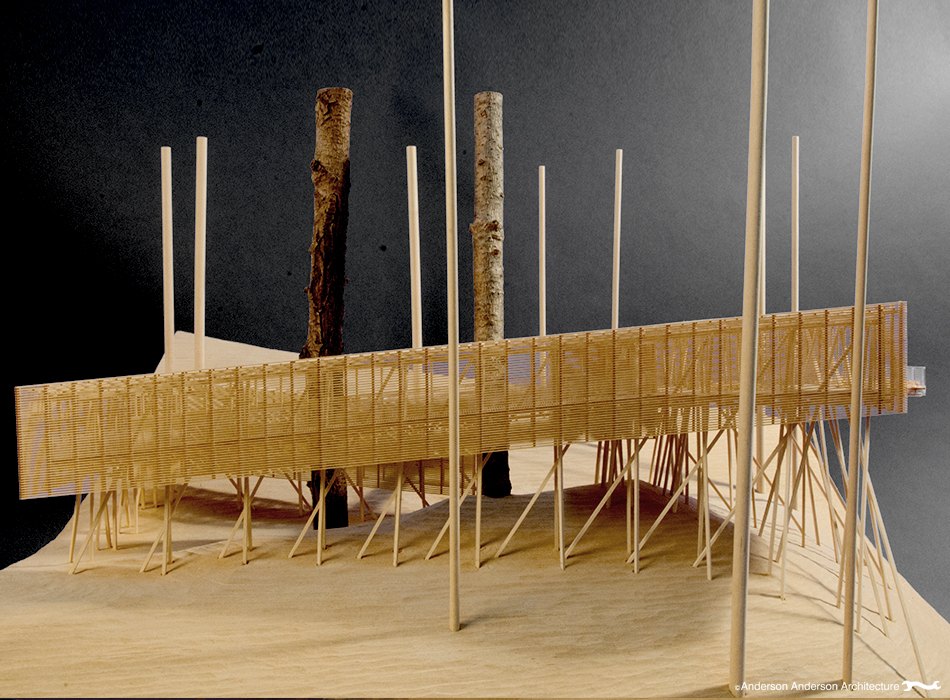

Working with Charles Anderson Landscape Architecture in Seattle, we designed four primary structures as interpretive centers and visitor facilities at various strategic points within the master plan for a new arboretum of native Northwest forestland. The nearby presence of a major highway, factory, and warehouse buildings caused us to suggest a revised theme to the arboretum’s educational mission and development plans. Although initially asked to create a space as natural and removed from human intervention as possible, we proposed to instead focus our design concept on the relationship between the built and natural environments, taking advantage of the positive aspect of the site’s easy access and visibility from the most highly traveled highway leading in and out of Seattle from the east. Rather than routing the arboretum entrance away from existing development and further encroaching on the forest, we repurposed the parking and other infrastructure of a defunct adjoining factory as a launching point at the edge of the forest from which to enter into an exploration of more appropriate examples of the interface between buildings and the natural environment. Wishing to demonstrate multiple strategies for buildings to relate sensitively to their sites, we designed all of the new structures, to be introduced into the forest itself, around a CNC-milled timber-frame system but deployed it in a different way for each interpretive center to create varying experiences: being underground with the roots of the trees, on the forest floor to focus on this habitat, and raised high on stilts up into the forest canopy itself. Instead of having a sharp contrast between the building and the surrounding landscape, the design concept is to provide a stepped progression of experience that is also a model and metaphor for the relationship between human intervention and the natural landscape.

The building is a completely foreign object within the natural landscape, but it is rendered in forms or materials taken from that landscape, successfully blending into a harmonious whole. This is juxtaposed with secondary “built” objects—trees planted in unnatural, buildinglike formations, showing human intervention in nature from another perspective.

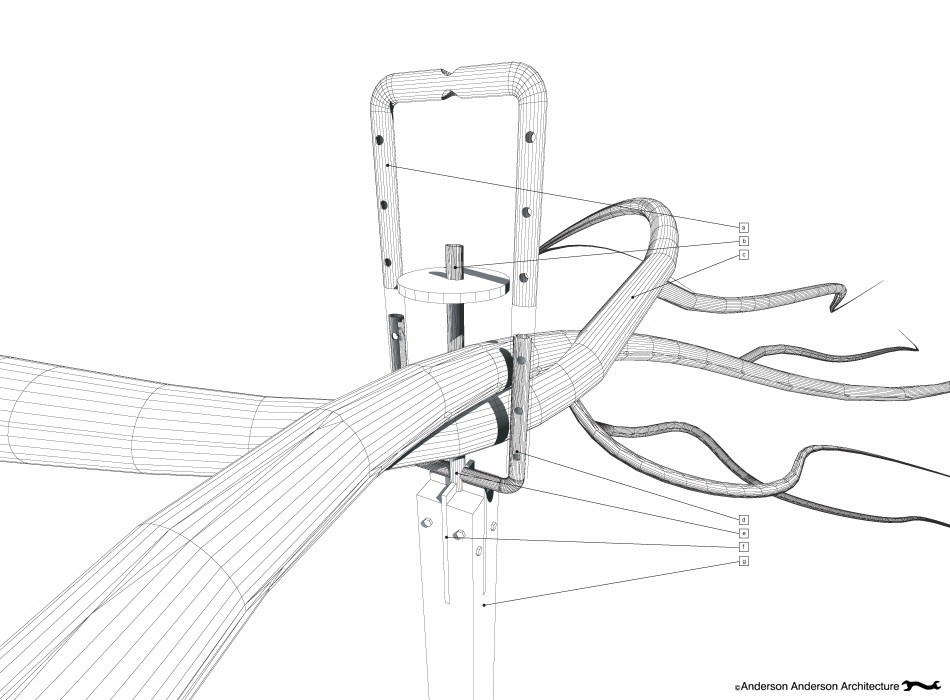

CNC Timber Framing

Timber framing is a building system that has been used for thousands of years and

is most often associated with the temple architecture of Japan, China, and Korea,

as well as Northern European structures evolving from the building traditions of

the Middle Ages. Traditional timber-framing techniques center around the intricate and often beautiful joinery work that connects the structural members, but these techniques are typically considered too labor-intensive and too weak for modern construction. With the advent of Computer Numeric Control (CNC) milling machines, however, much of the hand labor can be reduced, and exposed or concealed steel connectors can be used to make rigid connections. A resurgence of interest in timber-framing systems has contributed to a revival of historical forms, particularly in residential construction, but there has been relatively little use of this technology

in modern design.

Traditional timber framing is most often used as a post-and-beam structural system, where loads are transferred through a building on linear paths through massive timber elements. With the wall enclosure systems independent of the structure, there are many opportunities to develop dramatically open spaces with large openings of windows and interior or exterior walls that remain separate from the structure. Timber framing is compatible with other prefabricated building systems, such as panelized stud walls or SIPs panel systems, which can be used to form the non-load-bearing portions of a building.

Log buildings are a particular kind of prefabricated timber-framed system, typically incorporating load-bearing solid wood wall sections with more purely post-and-beam systems for their roof structures. The log home industry has introduced significant technological advances in log construction in recent years, and the production capability of working with these processes has progressed more quickly than

has any design evolution to take advantage of it. Although working with logs is still

a niche area of the construction industry, there are many interesting opportunities for expanding their use into more building types and directions.

As more and more timber-frame manufacturers invest in this new generation

of CAD/CAM machinery, there exist a growing number of sources for this technology

in all regions, although the factories tend to be most often located in the timber-producing regions of the United States and Canada, and in Northern Europe. It is interesting to note that the majority of the CAD/CAM milling machinery used in the North American timber-frame industry is designed and built in Germany.