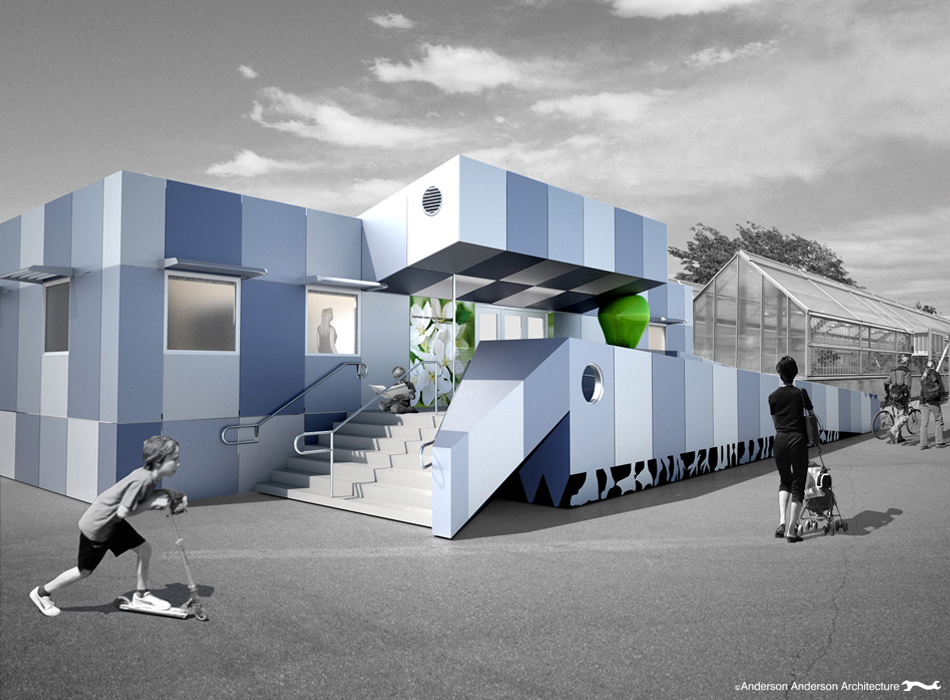

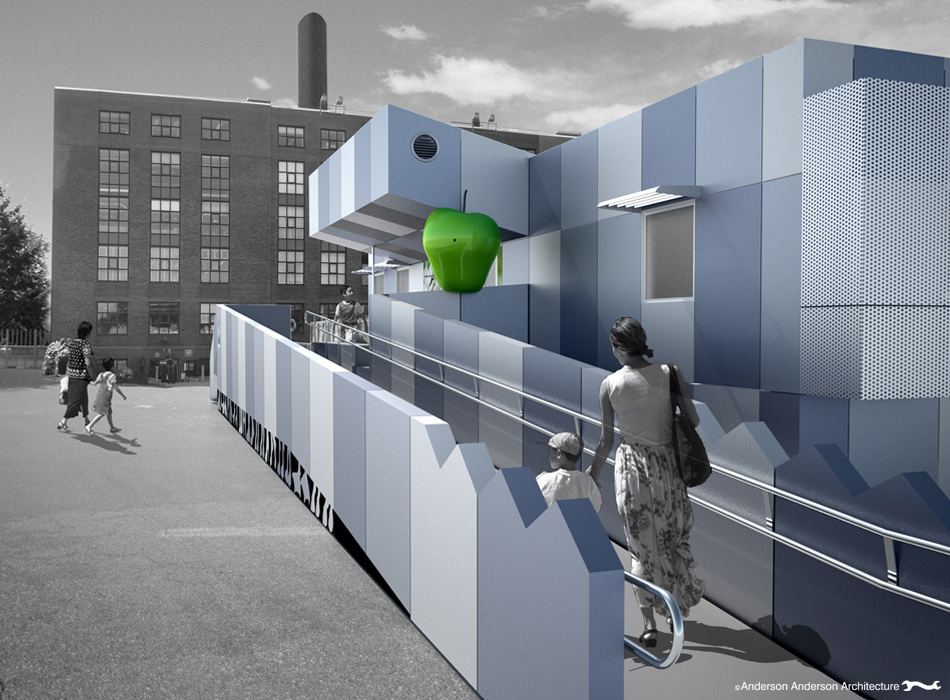

HARVARD YARD CHILD CARE CENTER

哈佛大学校园幼托中心

LOCATION: Harvard University, Cambridge, MA

PROJECT SIZE: 5760 sf

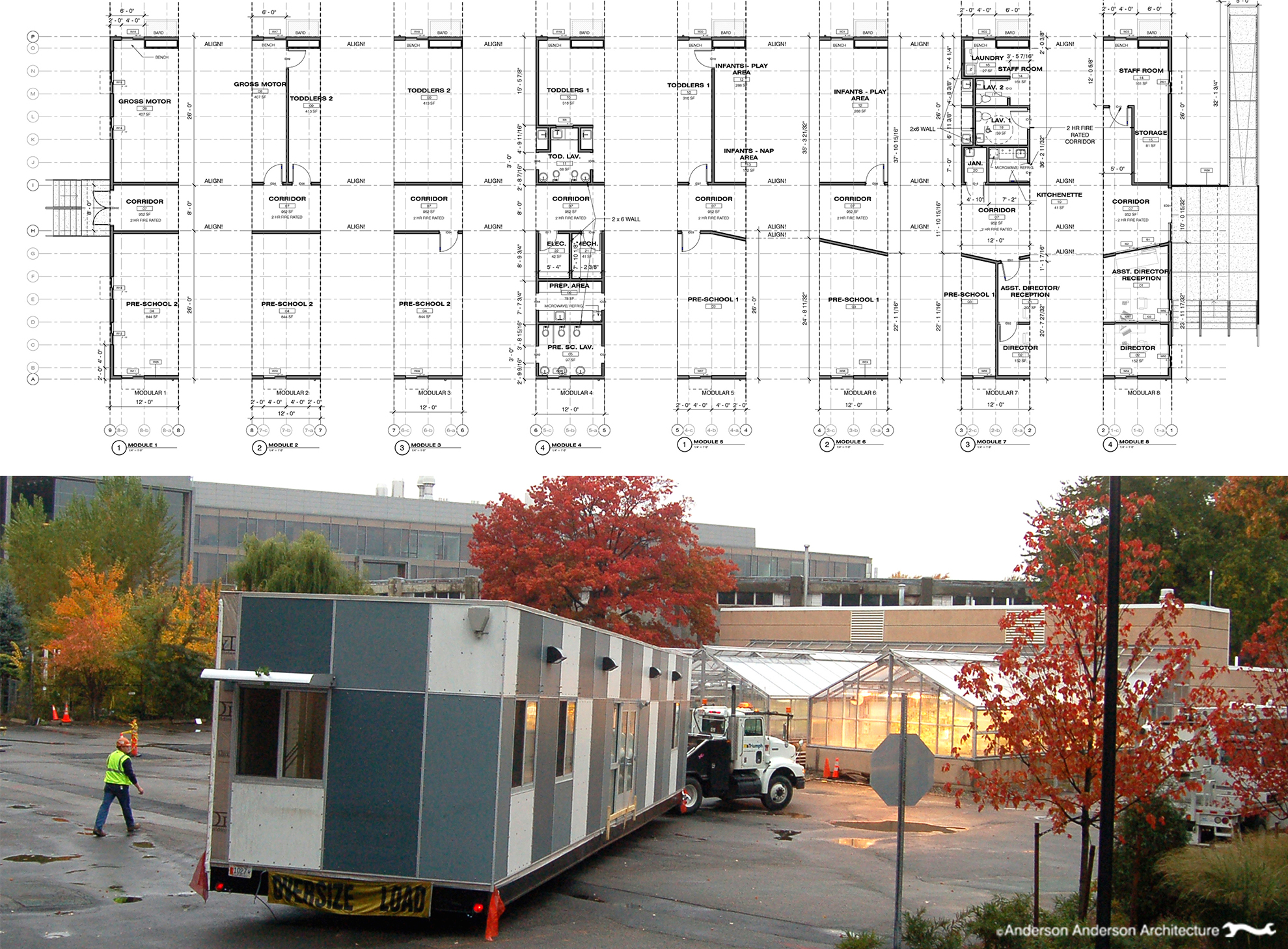

BUILDING TYPE: Preschool, Prefabricated modular steel and wood construction

AWARDS:

2011 Modular Building Institute Design Awards, Sustainable Design Category, for Harvard Yard Childcare Center, Cambridge, MA

2011 Modular Building Institute Design Awards, People’s Choice Award, for Harvard Yard Childcare Center, Cambridge, MA

2011 Exhibition of School Architecture Certificate Award, National School Board Association and American Institute of Architects, for Harvard Yard Childcare Center, Cambridge, MA

2010 Boston Society of Architects, Honorable Mention for Construction Innovation and Sustainability, Harvard Yard Childcare Center, Cambridge, MA

2010 AIA San Francisco Design Awards, Merit Award for Energy and Sustainability, Harvard Yard Childcare Center, Cambridge, MA

NARRATIVE

Harvard University commissioned a portable building to accommodate children from campus childcare facilities that are undergoing permanent renovation over the next several years. Initially expecting to use modular office trailers typical to the rental fleets of commercial modular builders, the project transformed into an ambitious prototyping project to produce a new standard for highly flexible, high quality, sustainable modular buildings that could compete financially with the standard, energy intensive and often unhealthy mass market products.

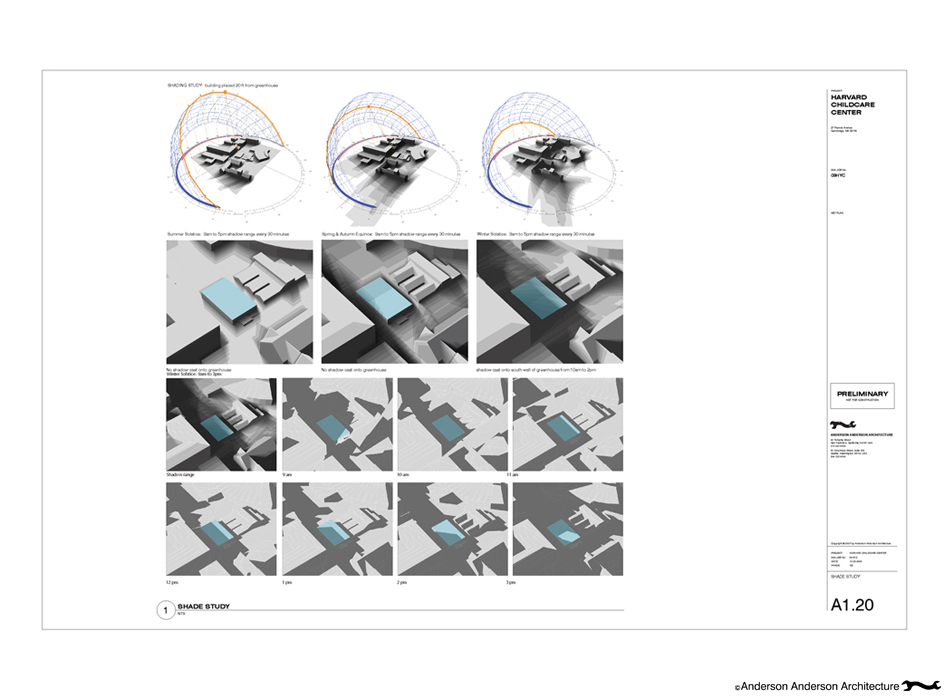

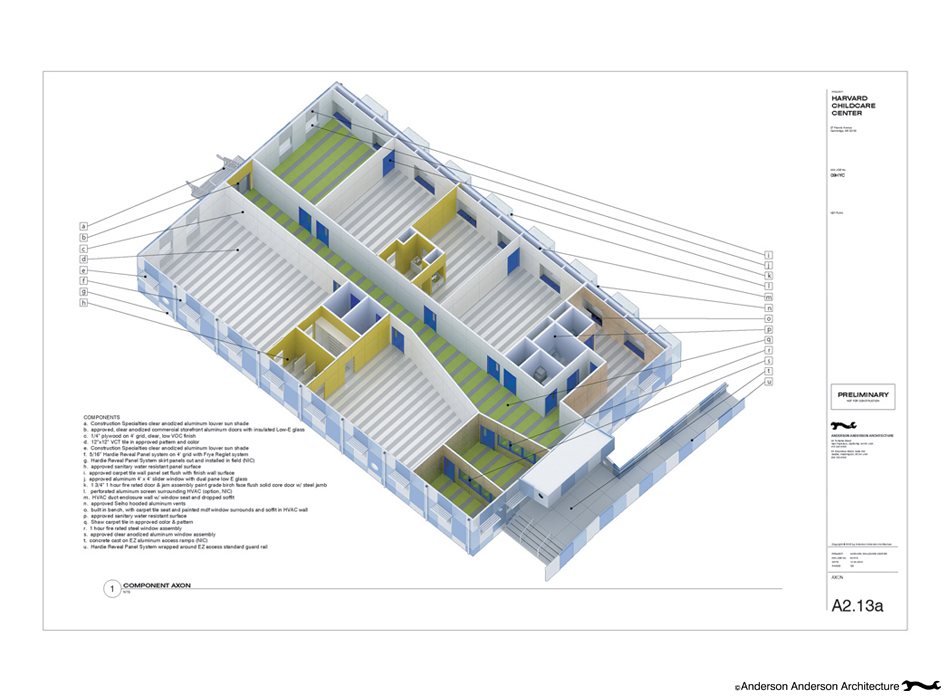

To accomplish this goal, the building components are based as closely as possible to the conventional sizes, configurations and fabrication systems typical to the modular industry. Within this rigid typology, construction systems were closely studied and streamlined at every opportunity. Standard materials and equipment were replaced with healthier, more sustainable and less energy intensive alternatives wherever this could be achieved within reasonable cost constraints and with minimal disruption to factory work line procedures. The resulting new standard module maintains the existing proportions and system logic dictated by transportation law and factory constraints, but revolutionizes quality in terms of ceiling height, acoustics, indoor thermal comfort, indoor air quality, natural light and ventilation, low carbon footprint, healthy materials and sustainable materials, equipment and energy use.